Introductio

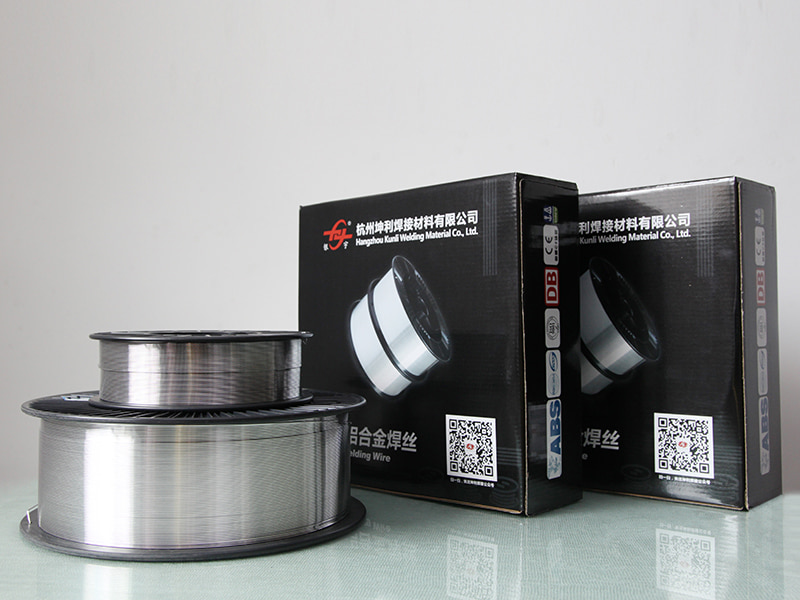

Porositas - minutissima decepta gasi - est communissima defectus in aluminio glutino et graviter in discrimen vitae lassitudines et robur stabilis pugillis. Nostra humilitas raritatis filler linea est, nostra obligatio premium integritatis ad pactionem. Consectetuer contentum moderamus e scaenico rudis condolentis per vacuum marcescentem, et oxydatum superficiem continenter removemus quae humorem in piscinam portant. Si filum ultramundum praebentes, officium fabricatoris aspe simplicificamus, curantes ut condiciones tabernam etiam minus quam perfectam praebentes, pactionem inde evenire requisitis gravissimis Non perniciosissimis (NDT) requisitis..

Specification

| Key Processus Imperium | Mechanica Tondenti (Die Tondenti) et Vacuum Degassing de Billet |

| Porosity Metric | Guaranteed volumetric poros <0.5% in normatum pugillo pads |

| Primarius fons | Hydrogenium (humidum et residua gas in conata) |

| Methodus packaging | Hermetically signatus, ffoyle-laminatis vel metallicis saccis / tympana |

| Test Obsequium | AWS D1.2, API 1104 transire, et ASME Sectio IX NDT signa |

Applications et Solutiones

-

Pressura vasa et Pipelines: Mandavit pro componentibus ad ASME Boilerum et vasis Cocles pressionem constructum ubi qualitas X-radius impellitur coacta.

-

Aerospace and Defensionis Structures: Articulorum oneris criticae ferentium exigunt raritatem voluminis sub-0,5% porositatem fracturae ac lassitudines perficiendi.

-

Subsea et Suboles Fabricatio: Welding components ad continuam demersam servitutem destinati ubi integritas alta structuralis est essentialis.

-

Summus Cycle Lassitudine Applications: Quaelibet structura subiecta constanti accentus inversio ubi vitia interna eliminari debent, ne rima initiatio fiat.

FAQ

- Q: Quae est principale causa porositatis in aluminio glutino?A: Hydrogenium. Aluminium facile dissolvit consectetuer gas in suo liquore. Sicut stagnum conglutinatum solidatur, solubilitas drastice guttae, et hydrogenium praecipitat, ut poris sphaericis intra metallum solidum capiatur. Fontes praecipue sunt humoris (ex oxydis, aere) vel gas residua in basi metalli/filli.

- Q: Utrum globulum lene globo significare porositate caret?A: No. Superficies species ad arcum stabilitatem et artem spectat. Porositas interna tantum detectabilis est per methodos voluminis Non-Destructivae Testis (NDT) sicut radiographiae X radiographiae vel ultrasonicae probationis.

- Q: Quomodo tonsura mechanica porositatem minuit?A: Tonsura mechanica removet filum externum stratum aluminii, quod plures oxydi superficiei continet et humorem adsorbuit. Hoc obstat quominus iidem contaminantes in piscinam coeruleam ingrediantur et gas hydrogenium generantes.