Introductio

Fabricatores de crassa aluminii lamina (super 10mm) in fabricandis, gravibus instrumentis, et infrastructura faciei immensam pressionem ad horas intensum glutino laboris minuendi. Filum nostrum alta depositio est solutio. Excursus glutino 400A ad 550A sustinendo et depositionis rates assequendo usque ad 7kg/hr (rationes manuales longe excedentes), significantes incrementa in fructibus dabimus. Hoc fit per conductivitatem superficiem auctam et districtum imperium super filum missile, quod filum excurrit aequaliter per velocitatem virtutis pastores sub gravi onere.

Specification

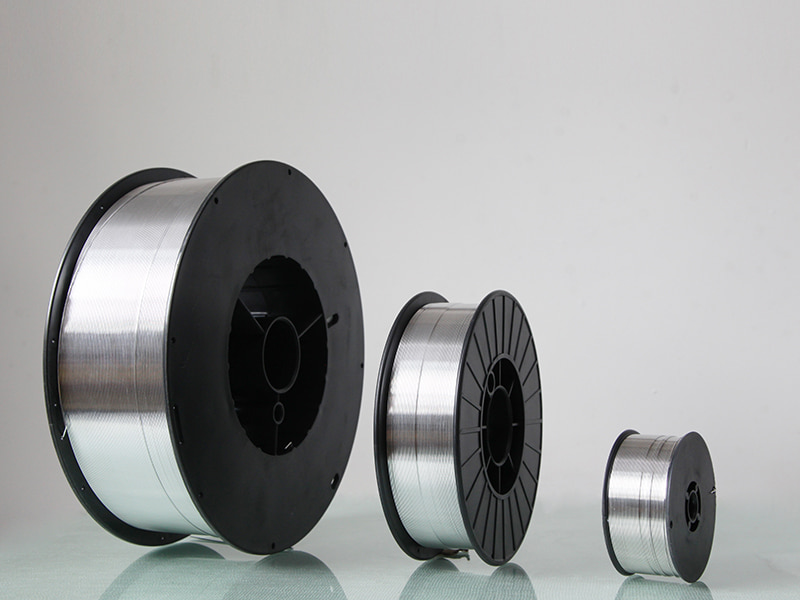

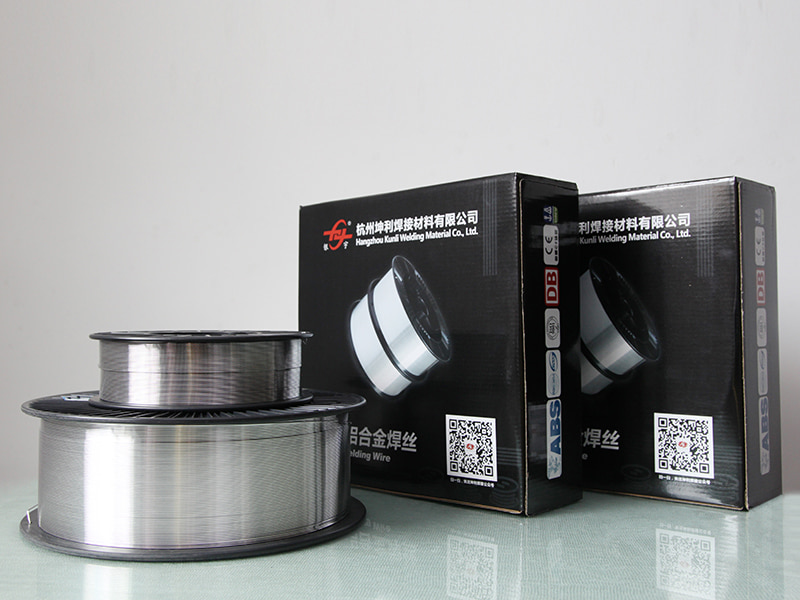

| Diameter Range | 1.6mm (0.062 in), 2.0mm (0.078 in), 2.4mm (0.094 in) |

| Scopum Current dolor | 350A ad 550A (GMAW-P et RAMULUS Translatio) |

| Depositio Rate (Target) | 4.5kg/hr ad 7.0kg/hr (fretus stannum/currente) |

| Requiritur Packaging | Talpa tympana (150kg ad 250kg) ad vitare frequentes commutationes |

| Clavis Alloys | ER5356, ER5183 (ob applicationes ad altiorem vim et volumen) |

Applications et Solutiones

-

Naves (Thick Plat); Coniungens magnas aluminium sectiones pro carinae carinae et structurae longinquae ubi densae laminae altae radicis depositionis requirunt et saltus implent.

-

Gravis Equipment and Machinery: Vehicula densissima membra constructionis vehicula, dump aliquet, viverra cursus et magna lacus.

-

Girth Welding de Lacus; Automated glutino longae summe in vasis pressionis et magnis diametris obterere utentes altae venae tandem vel gemini filis.

-

Summa Automation: Quaelibet applicatio robotica vel mechanizata, ubi cyclus tempus circumscribitur, copia metalli pacti requiritur ut volumen iuncturam impleat.

FAQ

- Q: Utrum summus calor input glutino temperare vires aluminii?A: Altus calor initus augere potest magnitudinem HAZ (Caloris Zonae affectae), ducens ad augendam admixtionem minuendam in calore tractabilium (sicut 6061). Diligens ergo moderatio temperaturae interpassi et celeritatis peregrinationis mandata est summus depositionis glutino.

- Q: Potestne filum altum depositionis adhiberi cum apparatu MIG vexillum?A: No. Princeps depositionis glutino fontes potentiae graves (500A) requirit facies refrigeratae aquae, et systemata valida nutriens apta tractandi venam altam et maiorem rigiditatem filum.

- Q: Cur mole packaging requiri ad altam depositionis glutino?A: Ad 6kg/hr depositio, vexillum 7kg FUSUS in tantum supra horam consumitur. Mole tympana (150kg) admittunt per dies continuos, continuas glutino, maxima efficientiae lucri processum depositionis pontificis.