Aluminium Welding Wire

Er5356 Aluminium Welding filum

5356 is about 5% Magnesium Aluminum filler metal which has high strength, high corrosion resistance and matches the color well with the parent metal after anodizing, recommended for welding casting and forging Al-Mg alloys with maximum 5% Magnesium and parts of wrought alloy of 5000 series, 6000 series, 7000 series, such as 5050, 5052, 5083, 5456, 6005A, 6061,6063,6082,7005 etc.

Maxime applicare ad supellectilem, ludis apparatu, compressa continens, naves, rail translationem et automotive industria et on.

Depictio producti

Welding Welding Welding ER5356 Aluminium Welding Est solidum Welding filum fundatur super aluminium et magnesium, quod late in Tig (Tungsten inerti Gas Welding) et Mig (metallum inertes Gas scuta welding) Welding de Aluminium Alloys. Eius principalis offendiculo elementum est magnesium (ad contentus est inter 4.5% -5.5%), quod est optimum corrosio resistentia et welding perficientur.

Productum characteres

Chemical Compositionem: Pelagus components includit aluminium, magnesii, Manganese, Chromium, etc.

Mechanica Properties: Typical Tensile fortitudo est 200-30 MPA, cedere vires est 83-207 MPA et duritia ranges ex 110-130 HV.

Melting Point Range: 1060-1175 ° F (571-635 ° C), idoneam ad varietate welding processibus.

Welding Characteres: Stabilis Arcus, Minus Spatter, Pulchra Formatio, idoneam omnes positionem Welding.

Applicationem missionibus et agri

Marine et Shipbuilding: Ob eius optimum corrosio resistentia, est maxime idoneam marine environments.

Automobile et machinery vestibulum, propter automobile partibus, pressura vasa, etc.

Aerospace, idoneus structural partes excelsis et corrosio resistentia requisita.

Sports apparatu et vehentem vestibulum, late usus debitum ad lucem pondus et princeps vires characteres.

Industria signa et cubits

Signa: Meets Aws A5.10 Latin, equivalent to almg5cr (a) in ISO (XVIII) CCLXXIII Latin.

Diameter: 0.8-2.4mm pro MIG welding et 1.6-6.0mm pro Tig Welding.

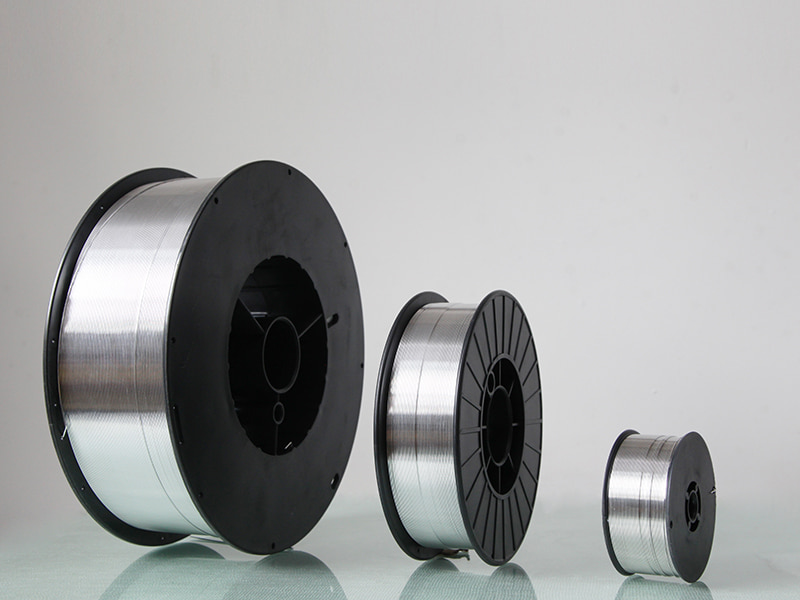

Packaging: A varietate packaging formae sunt praesto, inter plastic reo, metallum et tympanum packaging.

Er5356 Aluminium Welding filum

Ex Sinis

Venalicium Ad Mundum.

-

30+

IN GRAVIS INDUSTRIA technologiae SECTOR

-

35

Annos investigationis et experientiae

-

200+

COOPERATIVUS large R & D INSTITUTIONES

-

20+

Global COMMERCIUM NATIONES ET REGIONES

Veniens de Sina,

Venalicium Ad Mundum.

Plus quam 90% agri nostri operarii in background educationis professionalis et technicis habent, et multos annos experientiae in instrumento processus et conventus habent. Propter hoc ipsum coniunctum, dedicatum, auctorem, peritum et expertum ipsum dolor technologiae et fructus societatis continue renovari et emendari possunt.

Nuntius mitte nobis

Related Products

-

View More

View More

(V) CLIV Aluminium Alloy Welding filum

-

View More

View More

Er4043 Silicon Aluminium Welding filum

-

View More

View More

ER4047 Aluminium MIG Welding filum

-

View More

View More

ER5154 Al-mg Alloy filum

-

View More

View More

ER5087 Magnesium Aluminium Welding filum

-

View More

View More

Aluminium Welding Wire ER5183

-

View More

View More

Er5356 Aluminium Welding filum

-

View More

View More

Er5554 Aluminium Welding filum

-

View More

View More

Er5556 Aluminium Welding filum

-

View More

View More

ER1100 Aluminium Welding filum

-

View More

View More

Aluminium Welding ER5754 Welding

-

View More

View More

Er2319 Aluminium Welding filum

::: Novissima News :::

-

Eligendo ius Aluminium Welding filum: comparet ...

Sep 11, 2025

Intellectus Aluminium Welding filum Quid est Aluminium Welding filum? Aluminium Welding Wire Est per consumptable materia ...

-

Er4043 Silicon Aluminium Welding filum comprehe...

Sep 06, 2025

Introductio In modern Industrial Welding, Er4043 Silicon Aluminium Welding filum facta est late usus filler materiale...

-

Aliquam Rector ut ER5356 Aluminium Welding filu...

Sep 06, 2025

I. Introduction In modern industriae vestibulum, aluminium late solebat debitum ad suum lightweight, princeps vires, et corrosio re...

-

Comprehensive Rector ut Aluminium Welding filum

Sep 06, 2025

I. Introduction Aluminium Welding Wire Est necessaria filler materia in modern welding, maxime propter Welding Alumini...

-

Aluminium Welding filum Electio et Welding Guid...

Sep 05, 2025

Introductio Aluminium Welding , Ut a key technology in modern vestibulum, est late in aerospace, automotive vestibulum, const...

-

Aluminium Mig Status Manufacturers: Quid offerr...

Sep 03, 2025

In postulans orbem metallum fabricae, consequi consistent, summus integritas aluminium welds cards in factores saepe occultatum a visu...

Industria Information Extensio

More Information About Er5356 Aluminium Welding filum

Optimizing MIG & Tig Welding perficientur cum Er5356 Aluminium Wire

Cum opus cum Aluminium Alloys, eligens ius Er5356 Aluminium Welding filum potest significantly impulsum weld qualitas, vires et corrosio resistentia. Hoc versatile filler metallum est praecipue bene apta MIG et Tig Welding Applications, praesertim cum joining 5xxx series Aluminium Alloys communiter in marine, automotive et structural fabricae.

Quid eligere Er5356 enim Aluminium Welding ?

Er5356 stat ex inter Aluminium Welding filis ex eius V% Magnesium contentus, quae providet:

Altius Tensile Vitium (~ CCXC MPA) comparari ad Er4043

Melius crack resistentia in summus accentus applications

Superior rorum resistentia saltwater environments

Optimum Ductility pro structural et dynamic onus applications

Nam Welders opus in navi Hull reparationibus aut aluminium trailer fabricam, er5356 offert distincta commoda super alia filer filis. Et compatibility cum marine-gradu aluminium Alloys ut (V) LII, (V) LXXXIII, et (V) CDLIV facit eam a summo choice pro offshore welding projects.

MIG Welding Techniques cum ER5356

Cum profecta est MIG Welding Aluminium cum Er5356, propriis apparatu configuratione est crucial;

Commendatur parametri:

Filum Diameter: 0.8mm-1.2mm (0.030 "-0.045")

Tutela Gas: LXXV% Argon / XXV% Helium Mix (amplio penetratio)

Voltage Range: 18-22V (ad 1.0mm Wire)

Filum Feed Celeritate: 5-8 m / min

Ne commune Aluminium Mig Welding problems velut Porosity vel pauper eget:

Uti a dis technique (LeCle angulo 10-15 °)

Ponere propriis contactus tip ad opus spatium (10-15mm)

Ensure aluminium-specifica coegi rotulis ne filum deformatio

TIG Welding Applications

Nam praecisione opus in aluminium pipe Welding aut tenuis METIALIS Aluminium Fabrication, TIG WELDING cum ER5356 producit mundus, summus qualitas welds:

Optimal Tig Occasus:

Tungsten Electrode: II% Ceriiated aut Zirconiated

Ac Libra: LXX% en (Purgato actio)

Preheat, 150-250 ° F Créditis sectiones (> 6mm)

Filler virga diametrum: par ad base metallum crassitudine

Anodizing compatibility de Er5356 facit ut potior pro visibilia welds ubi uniformis metam non requiritur, etsi non potest ostendere levi griseo tint comparari ad ER4043 scriptor obscurior species.

ER5356 vs. ER4043: Discriptis Ius Filler

| Parameter | ER5356 | ER4043 |

|---|---|---|

| Tensile viribus | CCXC MPa | CLXXXVI MPA |

| Elongatio | 10-1V% | 12-18% |

| Color post Anodizing | Lumen griseo | Tenebris griseo |

| Magnesium contentus | 5% | 0% |

| PROPRESSUS | Marine, structural | Castings, exornantur |

| Corrosio resistentia | Optimum (saltwater) | Bonum |

| Cracking Weld resistentia | Altum | Moderor |

Faq

Q: Potest Er5356 adhiberi ad Welding (VI) LXI Aluminium?

A: Sic, sed post-weld calor curatio potest esse opus ad maximum vires in (VI) LXI applications.

Q: Quid est optimus tutum Gas ad Er5356 MIG welding?

A: A LXXV% AR / XXV% ille misce praebet meliorem penetrationem densior aluminium sectiones.

Q: Utrum ER5356 opus ad pulsed MIG welding?

A: Absolute - pulsed Mig reduces calor input et amplio weld speciem cum ER5356.