Introductio

Porositas, seu gasum intra metallum conubium evacuat, graviter implicat vires mechanicas et lassitudinem vitae. Fit quod hydrogenii, valde solutum in aluminio liquido, virtualiter insolubile est, cum metallum solidatur, ac vaporem ad bullas formandas cogens. Nostra solutio excedit vexillum purgatio. Ipsam metallicam filliginem regemus, superficies pristina est, interna compages densa est, et impedimentum umoris completa est impedimentum. Hic accessus proactivus efficit ut metallum filli non sit hydrogenii fons, umbilicus movens ad praeparationem metalli basim propriam et processum temperantiae usoris.

Specification

| Key Defectus Targeted | Porosity weld (Hydrogen Entrapment) |

| Processus Feature | Provectus Chemical Etching, Superficies De-oxidationis |

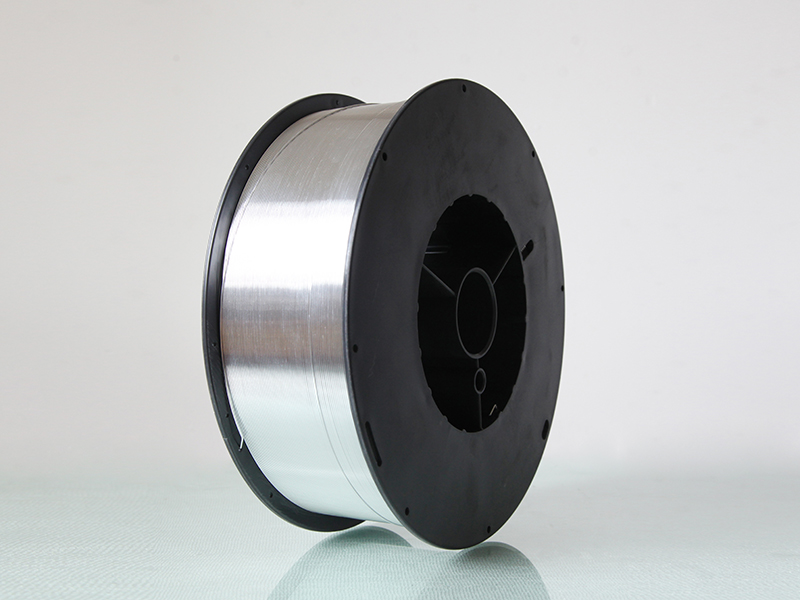

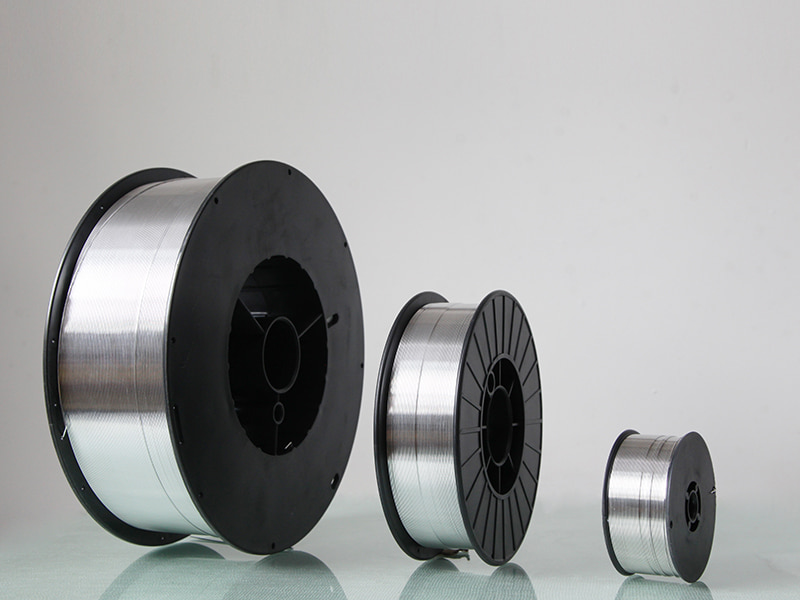

| Packaging | Vacuum signatum, Foil-Laminated Packaging with Desiccants |

| Superficies Condition | Humorem et Oxide Content |

| Testis | Consuetudo radiographica probatio turpis firmare humilis poros index |

Applications et Solutiones

-

Pressura vas Welding: fabricatio piscinarum et vasorum ubi porositas interna ingrata est ob suam integritatem pressionis et acceptationis NDT.

-

Summus Integrity compages structuralis: Welding partes ubi lassitudo loading expectatur, porositas agit ut resurrectio accentus qui lassitudinem rimas inchoat.

-

Automated Welding: Usus est in magna celeritate, cellulae roboticae glutinis ubi manualis purgatio spool filum impractical et filler constantia critica est.

-

Crassissima Sectio Nuptialis: Usus ad plures transitum glutino, ubi magnum volumen conglutinatum totam potentiam auget ad hydrogenii cumulum ac porositatem formationis.

FAQ

- Q: Quid est prima origo hydrogenii in aluminio glutino?A: Humor primarius fons est. Hoc includit humorem in oxydatum porosum iacuit in basi super superficiem metalli, humor in gas protegendo, vel humor in superficie fili filli adsorditus.

- Q: Quid facere potest welder ad porositatem reducere?A: Clavis gradus includunt penitus purgationem metalli basi (descendendo et removendo iacuit oxydatum modo ante glutino), ut siccum, altum puritatem protegens gas (exempli gratia Argon), et confirmans filum fillii est mundum et siccum.

- Q: Quomodo porositas mensuratur in pactione finali?A: Porositas solet quantitatis utens experimento radiographico (RT) (X-ray). Codices denotant maximam magnitudinem et distributionem pororum permissam. "Porositas Index" communis industriae metrica est