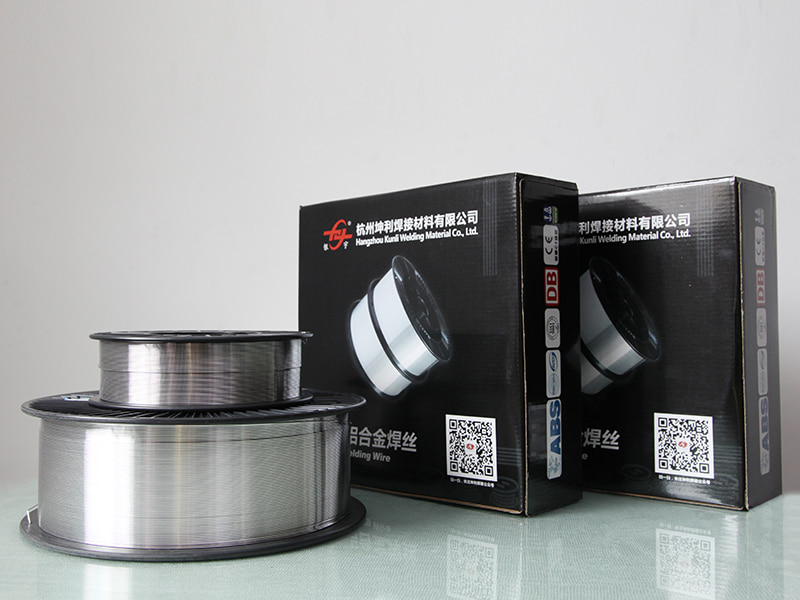

Aluminium Welding Wire

Aluminium Welding ER5754 Welding

(V) DCCLIV est de III% Magnesium aluminium Filler metallum quod est medium fortitudinem, meliora maris corrosio resistentia, commendatur ad Welding constructione partium (V) LXXXIII, 6061,6063, sicut etc (XXXIII

Depictio producti

Aluminium Welding Welding Welding Er5754 Est summus perficientur filler materia disposito enim Welding 5xxx series Aluminium Alloys (ut (V) LXXXIII, (V) DCCLIV, etc.), quod obsequitur cum American Welding Society (A5.10 Latin. Eius chemical compositionem valde matched cum parente materia, et habet optimum corrosio resistentia et welding processability. Est late in shippuilding, marine ipsum, eget continentia et aliis agris.

Core characteristics

Chemical Compositionem Optimization

Magnesium contentus: 3.0% -3.8% (typical valorem), ensuring quod vires et corrosio resistentia de weld sunt consistent cum parente materia.

Minimum ferrum humilis Silicon: reducere negative impulsum impudicitiis in weld lento et vitare scelerisque fregisset tendentia.

Mechanica proprietatibus

Tensile fortitudo: ≥280 MPa (specifica valorem accommodetur secundum processus).

Elongatio: ≥12% (ut weld plasticity).

Durness: 80-100, Balancing viribus et processability.

Corrosio resistentia

Et weld est repugnant ad marinam et industriae atmosphaerica corrosio et idoneam dura environments.

Verified a sal imbre test (ut ASTM B117), quod corrosio rate est minus quam V% de parente materia.

Welding processability

Stabilis Arcus: Minus Spatter sub DC Reverse Connection (DCEN), pulcherrima Weld formation.

Bonum fis stagnum fluiditatem apta omnibus situ Welding (plana Welding, vertical Welding, caput welding).

Application missionibus

Naufragium

Hul structuram, deck, bulkhead Welding, occursum certification requisita classificium societates ut DNV et Abs.

Typical casibus: Aluminium Alloy CELOX Hull Splicing, LNG Liquid Cargo Tank Sectorum Welding.

Marine ipsum ipsum

Offshore platform, oleum repono cisternina, marcida pipeline welding, resistite marcescet corrosio et accentus corrosio elit.

Eget et cibum industria

Corrosio repugnans continens et Pipeline ratio welding, secundum FDA et asme signa.

Translatio

High celeritate agmine corpus et automobile Lightweight structural partibus Welding, accipit rationem fortitudinem et pondus reductionem elit.

Architecture et ornamentum

Aluminium Alloys corteps Wall, ostium et fenestram artus welding, ut lenis species et structural salutem.

Suasiones ad usum

Pre-Welding praeparatio

Mundare superficies parentis material (removere oleum et cadmiae film), et facere in sulcus (V-informibus et U-informibus).

Preheat densissima laminis (> 25mm) ad 100-150 ℃ ad redigendum periculum scelerisque rimas.

Welding Parameter Optimization

Usus pulsum MIG welding (si opus) ut amplio welding qualis tenui laminis.

Control Temperatus ≤150 ℃ ad vitare grossum grana.

Post-Weld Treatment

Tere de weld excessus altitudo ad idem gradu ut parens materia, et praestare X-radius vel ultrasonic vitium deprehensio (secundum vexillum).

Exercit accentus relevium calor curatio, si necessarium (ut T6 rei publicae parens materia).

Qualis Certification et Signa

A5.10 A5.10 ad propinquos meos ad propinquos meos A5.10, ISO (XVIII) CCLXXIII ISO (XIV) CLXXV, etc.

Providere Material Certification (MTC) et Tertius-Party Test Renuntiationes (ut SGS, Tüv) .

Aluminium Welding ER5754 Welding

Ex Sinis

Venalicium Ad Mundum.

-

30+

IN GRAVIS INDUSTRIA technologiae SECTOR

-

35

Annos investigationis et experientiae

-

200+

COOPERATIVUS large R & D INSTITUTIONES

-

20+

Global COMMERCIUM NATIONES ET REGIONES

Veniens de Sina,

Venalicium Ad Mundum.

Plus quam 90% agri nostri operarii in background educationis professionalis et technicis habent, et multos annos experientiae in instrumento processus et conventus habent. Propter hoc ipsum coniunctum, dedicatum, auctorem, peritum et expertum ipsum dolor technologiae et fructus societatis continue renovari et emendari possunt.

Nuntius mitte nobis

Related Products

-

View More

View More

(V) CLIV Aluminium Alloy Welding filum

-

View More

View More

Er4043 Silicon Aluminium Welding filum

-

View More

View More

ER4047 Aluminium MIG Welding filum

-

View More

View More

ER5154 Al-mg Alloy filum

-

View More

View More

ER5087 Magnesium Aluminium Welding filum

-

View More

View More

Aluminium Welding Wire ER5183

-

View More

View More

Er5356 Aluminium Welding filum

-

View More

View More

Er5554 Aluminium Welding filum

-

View More

View More

Er5556 Aluminium Welding filum

-

View More

View More

ER1100 Aluminium Welding filum

-

View More

View More

Aluminium Welding ER5754 Welding

-

View More

View More

Er2319 Aluminium Welding filum

::: Novissima News :::

-

Optimising ER5154 Wire Welding for High-Speed

Nov 28, 2025

Usus materiae ut ER5154 Al-Mg Alloy Wire magni momenti est pro industriis quae robust, corrosio-repugnantia structurarum...

-

Key Surface Metrics pro 5356 Wire Feeding

Nov 26, 2025

Pro B2B procurationis professionales opera- tiones glutino magno volumine servientes - chassis automotivae ad structuras marinas criti...

-

Usura Aluminium Alloy Welding Wire in Fabricati...

Nov 24, 2025

Aluminium Alloy Welding Wire , ut specialitas materia bilibri, aluminium connectit in variis processibus fabricandis. Ex alumini...

-

Quomodo ER4943 emendavit certum aluminium gluti...

Nov 21, 2025

Renovavit operam ad filler electionis et cibationis firmitatem, multas iunctiones fabricationis ad consumabiles retractandas admonuit,...

-

Quid Fuels Aluminium tortis Wire Demand?

Nov 19, 2025

In perenni innovatione conductivity et technologiae connectivitatis, Aluminium filum tortis emersit ut egregium facinus, aptissimum ad...

-

Discriptis Aluminium TIG Wire pro Weld Constant...

Nov 17, 2025

Aluminium TIG glutino exactionem in singulis stationibus exigit – ab communi praeparatione ad ultimam inspectionem. Integrum huic proc...

Industria Information Extensio

More Information About Aluminium Welding ER5754 Welding

Aluminium Welding ER5754 Welding In electrica vehiculum altilium tray vestibulum

Et growing demanda in lightweight et summus viribus aluminium Alloys in Electric vehiculum (Evident) Welding WELDING FAMILIARIS FACITIS ER5754 Aluminium WELDING FALLE A Critica Fabriced. Ut automakers prioritize pondus reductionem extend altilium range, 5xxx serie aluminium filler filis quasi er5754 offer optimum corrosio resistentia et weldability, faciens ea specimen ad marine-gradus aluminium welding et eget structural components.

Quid ER5754 maluit pro Pugna Trays?

Alii Aluminium Welding Wires ad Automotive Applications, ER5754 stat ex ejus:

Magnesium content High (~ 3.1%), enhancing vires sine calor curatio (non-calor-treatable mixe).

Superior corrosio resistentia, crucial pro altilium septisque obnoxia patere dura environments.

Minimum resiliunt sensum, reducendo defectus in summus celeritate robotic welding processibus.

A key competitor, Er5356 Aluminium Welding filum, est etiam popularis sed habet leviter inferior lassitudine resistentia in Welded articulis, faciens Er5754 est melius arbitrium ad structuram aluminium Welding in Melius.

Optimizing Er5754 WELDING parametri ad altilium scrays

Ad consequi summus qualitas welds in aluminium altilium tray vestibulum, welding parametri debet esse diligenter imperium:

| Parameter | Commendatur occasum | Technical consideratione |

|---|---|---|

| Filum diameter | 1.2mm - 1.6mm | Prout densissima aluminium welding (3-8mm altilium tray panels) |

| Protegens Gas | C% Argon aut AR / et miscere | Reduces Porosity in Marine-gradu aluminium welds |

| Travel Celeritate | 30-50 cm / min | Impedit Aluminium Weld fregisset In summus accentus locis |

| Voltage | 19-23v | Optimal est Pulsum Welding Aluminium applications |

| Filum feed celeritas | 6-8 m / min | Statera depositione rate et Weld bead species |

| Gas fluunt rate | 20-25 CFH | Critica Humilis-Porosity Aluminium Welds |

Surrexit trends: Er5754 in viridis vestibulum

Cum sustineri becoming a prioritate, recyclable aluminium welding filum quasi ER5754 est adipiscing tractus. Et compatibility cum post-weld Anodizing et Eco-amica welding processibus facit eam futurum-probationem electio pro altilium causa welding.

Nam manufacturers vultus parumper humilis-sumptus aluminium welding filum cum altum perficientur, er5754 praebet statera inter Weld vires vs. Ductility, faciens illud a summo colligunt in automotive et Marine Aluminium Fabriced.