Introductio

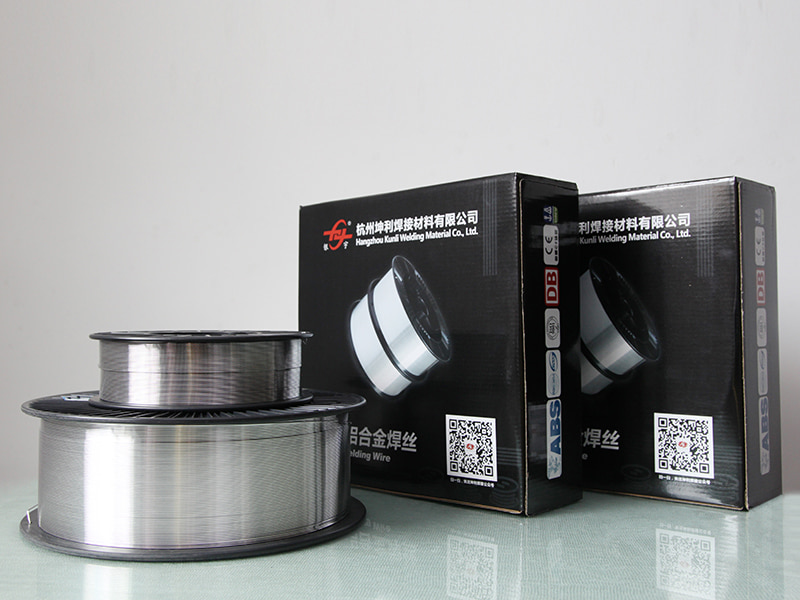

Pulsus MIG glutino est industria vexillum ad qualitatem, altam celeritatem aluminii fabricandi, offerens temperatum calorem input of TIG cum productione MIG. Intellegimus felicitatem in GMAW-P cardine constantiae consumabilis. Fila nostra cum propria extractione perit et superficies conficiuntur ut efficaciam electrica contactus augeant et friction in aquaeductu minuant. Hoc signum electrica firmum praestat necessarium ad programmatum machinae glutino ad synchronizationem arcum perfectam conservandam, defectus liberorum contrahit cum minimal spatto et praestanti aesthetico globuli profile tradens..

Specification

| Processus welding | GMAW-P (Pulsed Gas Metal Arc Welding) |

| Clavis Alloys | ER5356 (High strength), ER4043 (Flow/Cack Resistentia) |

| Diameter Tolerantia | ±0.01mm maximae declinationis |

| Superficiem Conclusio Metric | Optimized μ-olim resistentia contactus arcui stabilis ignitionis |

| Requiritur Winding | Subtilitas Stratum Vulnus (PLW) pro perfecta pascens celeritate |

Applications et Solutiones

-

Tenuis ad medium Aluminium Crassitudo; Materiae glutino ab 1.5mm ad 6mm ubi calor initus moderatus est essentialis ad praecavendam corruptelam.

-

Aesthetic Welds: Fabricatio partium visibilium in structuris autocinetis, trailers et architecturae structurae ubi tenuis forma desideratur.

-

Positio Welding (Vertical/Oerhead): Humilis calor, domitus stillicidium translatio Pulsus MIG, superiorem efficit glutino ex- positione, comparato imbre translato tradito.

-

Robotic Welding Cellae: Essentiale pro alta velocitate systemata automated quae iterabile, firmum arcui notae constanti qualitati articulari constanti et intricatae programmationis robotae reductae sunt..

FAQ

- Q: Quid est principale beneficium utendi pulsum MIG super vexillum RAMULUS Transfer pro aluminium?A: Pulsus MIG vim praebet ad imbrem transferendum dum calor input humilis in background phase servans. Hoc evenit in guttae moderatae magnitudinis, minus distortionis, et melioris temperationis pro tenuium materiarum et extra positione welds.

- Q: An filler filum meum opus ut valde purgari debet pro Pulsus MIG?A: Absolute. Quaevis superficies contaminans (oxidum, oleum) in filum rumpit contactum electricam, ducens ad inconstantiam pulsus formationis, arcus instabilitatem et porositatem, quae finem subtilitatis processus superat.

- Q: Potest uti Pulsus MIG pro glutino cast aluminium?A: Ita. Cum fillers ER4043 paribus cum alto fluxu similis, pulsus MIG exactam potestatem super conlectus praebet, optimum processum faciens ad sectiones aluminii iactus crassiores reparandas sine excalfaciendo.