Introductio

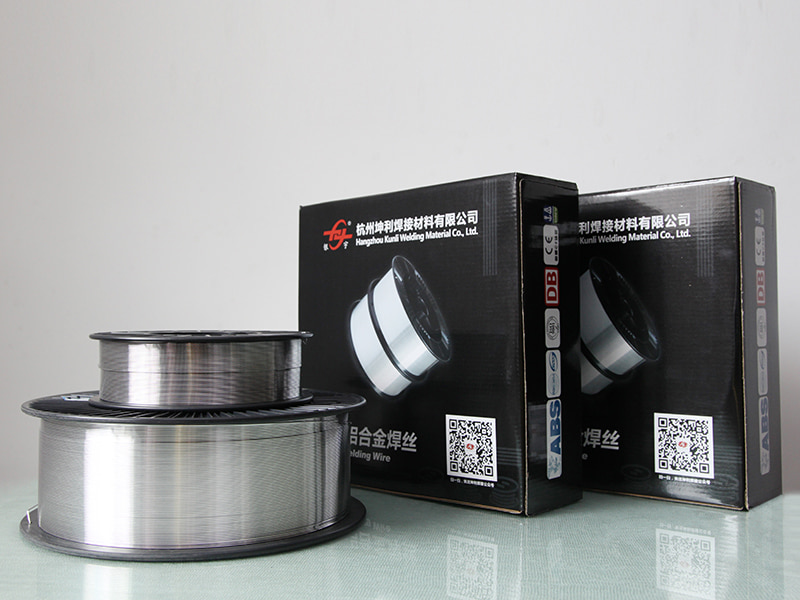

Ardens praecisio est processus vitalis in applicationibus sicut caloris commutatorii, ubi effluxus rectitudo et constantes virium iuncturae precipui sunt. Summus Silicon aluminium fabricamus materias fillores specifice formatas ad Operationem aeream optimize. Fila nostra pluma fluiditatis aucta et subtilis iugi liquatio ut penetrationem iuncturam integram sine basi metalli liquefaciens curet. Haec peritia in productione fili summae siliconis, coniuncta cum packaging quae superficiem filum tuetur, iterabilem et altam integritatem efficit in articulis tam manualibus quam automatis fornacis bracteis lineis..

Specification

| Alloy Focus (AWS) | ER4047 (AlSi12), ER4043 (AlSi5) |

| Exustus Range (ER4047) | 577∘C−582∘C (Prope Eutectic) |

| Key Property | High Capillary Action, Excellent Fluidity, Low Tab |

| Flux Compatibility | Optimized ad usum cum epiphoris communibus brazing (exampla, kalium fluoroaluminatum) |

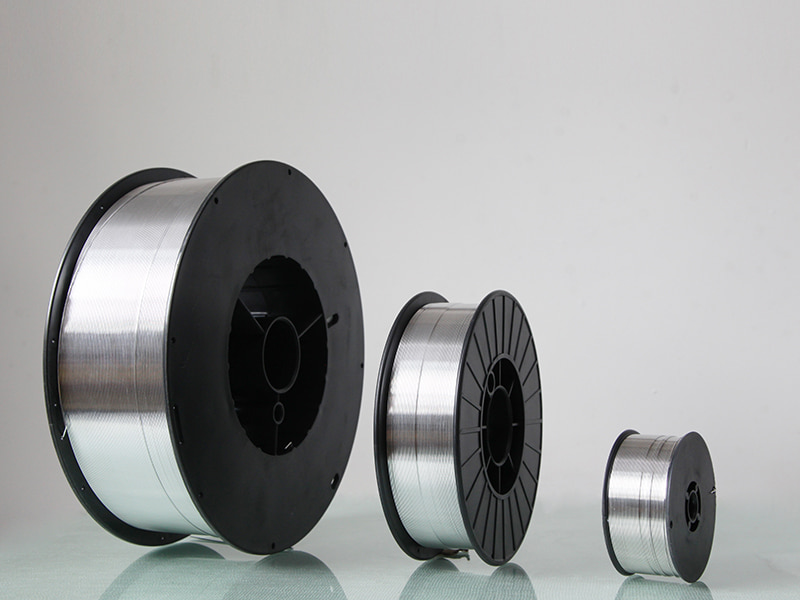

| Typical Diameter | 1.6mm ad 3.2mm pro TIG/Torch usus; parvas virgas pro manualibus inserendis |

Applications et Solutiones

-

HVAC/Refrigeration Systems: Colubri aluminii aerei, multiplices, et tubi collectae in caeli condiciones et caloris sentinarum unitates.

-

Automotive Caloris Commerciatores: Radiatores aerei, intercoolers, et frigidiores olei, saepe utentes filum fluxum cored vel filum nudum cum fluxu Nocolok.

-

Tenuis-Walled Component Joining: Applicationes, ubi calor initus glutino causaret incendium per vel nimiam corruptelam, cum solutionem emissam corruptelam praelatam efficiat.

-

Mittite-ad-connexiones: Coniungens dissimiles aluminii partes ubi summus contentus Pii pontes in differentiis metallurgicis.

FAQ

- Q: Quid est differentia principale inter aluminium glutinum et aluminium brazing?A: Welding liquescit et conflat base metalla; brazing metallum basim infra punctum liquescens calefacit et cum metalli filli (sicut ER4047) utitur cum puncto inferiore liquescens in iuncturam per actionem capillarem influendi.

- Q: Possumne uti ER4043 pro brazing?A: Ita, ER4043 (5% Si) adhiberi potest, sed ER4047 (12% Si) plerumque praefertur pro parte inferiore liquescens, fluiditatem superiorem et tutiorem marginem temperaturae contra basim metallicam liquescens praebens.

- Q: Estne fluxus requisitus ad aluminium brazing?A: Ita fere semper fluxus requiritur ad aluminium oxydatum chemicum removendum tenax, permittens liquorem plenoris metalli madefaciendi et trans superficiem iuncturam efficaciter fluere. Exceptiones sunt tantum pro vacuo brazing.