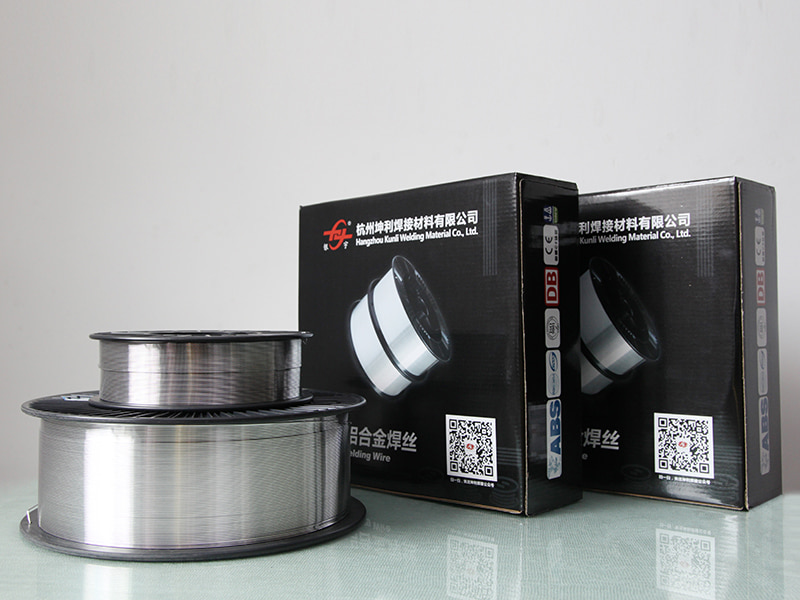

Aluminium Welding Wire

Special Al Alloy Welding Welding

Contained Sc, Magnesium Aluminum filler metal which has high strength,crystal structure excellent seawater corrosion resistance,and crystal structure is distributed uniformly and small cubic, recommended for welding the construction of parts of 5000 series, 6000 series, 7000 series and specially for Al-Mg-Sc and Al-Zn-Mg-Sc alloy . Maxime applicare ad aerem et spatii, Millitary, Rail transit et Auto Mobile Industries.

Depictio producti

Special Al Alloy Welding Welding Product Features

Optimum altum temperatus perficientur: et Welding filum habet optimum summus temperatus vires et serpere resistentia a addendo aliquid refractorium metallum elementis, et potest esse firmum welding effectus in altum temperatus environment.

Bonum Welding euismod: et liquescens processus est firmum et non est spatter. Welding filum habet bonum fluunt et expandit inter stratis, et non est facile ad defectus ut latus muro unfusu, quod formare pulchram et defectum libero, quod potest formare et defectus libero weld.

Excellent crack resistance and mechanical properties: Taking 2195 aluminum-lithium alloy welding wire as an example, its fusion welding joint is mainly composed of α-Al, Al₂Cu, Al₃(Ti,Zr) phases, with excellent crack resistance and mechanical properties, extremely low crack sensitivity, and the tensile strength of the joint at room temperature is about 390MPa, and the elongation is 6.3%.

Productum parametri

Material: maxime composito aluminium et varietate mixturae elementa, in specifica compositionem erit adaequatum secundum diversas applicationem requisita.

Diametrum, communia Diametrum specifications sunt 1.2mm, 1.6mm, etc., et alias diametri potest etiam ut customized secundum elit elit.

Longitudo, solet suppleri forma spools et longitudinem inter spolium potest customized secundum elit.

Working Current: Plerumque, Dcep (Direct Current Reverse Connection) Current non requiritur.

Working Temperature: operate ad vexillum temperatus.

Application missionibus

Aerospace agro: propter vestibulum et reparandis aircraft structural partes, engine partes, etc., ut MMCXCV Aluminium-Lithium Alloy Welding filum potest esse propter Welding partibus in aerospace engineering.

Automobile Vestibulum Industria, idoneam ad Welding de automobile corpora, engine partes, etc, et in occursum requisitis autocineti vestibulum ad Welding qualitas et efficientiam.

Machinery Vestibulum Field, potest adhiberi Welding de variis mechanicis partibus, ut aluminium alloy tabulae, robotic arma, etc.

Electronic et Electrical Industry: Non est quoque late in Welding of Electronic Equipment Housings, radiators, etc.

Special Al Alloy Welding Welding

Ex Sinis

Venalicium Ad Mundum.

-

30+

IN GRAVIS INDUSTRIA technologiae SECTOR

-

35

Annos investigationis et experientiae

-

200+

COOPERATIVUS large R & D INSTITUTIONES

-

20+

Global COMMERCIUM NATIONES ET REGIONES

Veniens de Sina,

Venalicium Ad Mundum.

Plus quam 90% agri nostri operarii in background educationis professionalis et technicis habent, et multos annos experientiae in instrumento processus et conventus habent. Propter hoc ipsum coniunctum, dedicatum, auctorem, peritum et expertum ipsum dolor technologiae et fructus societatis continue renovari et emendari possunt.

Nuntius mitte nobis

Related Products

-

View More

View More

(V) CLIV Aluminium Alloy Welding filum

-

View More

View More

Er4043 Silicon Aluminium Welding filum

-

View More

View More

ER4047 Aluminium MIG Welding filum

-

View More

View More

ER5154 Al-mg Alloy filum

-

View More

View More

ER5087 Magnesium Aluminium Welding filum

-

View More

View More

Aluminium Welding Wire ER5183

-

View More

View More

Er5356 Aluminium Welding filum

-

View More

View More

Er5554 Aluminium Welding filum

-

View More

View More

Er5556 Aluminium Welding filum

-

View More

View More

ER1100 Aluminium Welding filum

-

View More

View More

Aluminium Welding ER5754 Welding

-

View More

View More

Er2319 Aluminium Welding filum

::: Novissima News :::

-

Quomodo condere ER5183 Welding Wire to maintain...

Jan 07, 2026

Quilibet peritus weder sensit gravamen tractandi poros, fragilis, glutinosa, vel inaequales capitis penetrationem, quamvis solida mach...

-

ER5183 Welding Wire vs. ER5356: When should you...

Jan 05, 2026

In specialioribus mundi aluminii fabricationis, rectam filli metallicam eligens est consilium criticum ipsum, quod integritatem struct...

-

Key factores considerare eligens Aluminium Allo...

Jan 02, 2026

Periti welders et fabricatores sciunt clavis ad validum Aluminium welds bene incipit antequam arcus accendatur. Cum opus est instructu...

-

Quam ad Optimize Welding Occasus Cum Using ER51...

Dec 31, 2025

Aluminium cooperans praesentat provocationes singulares, quas multi welders quotidic offendunt. Cum vis Aluminium Welding Wire ER5...

-

Quomodo Design Electio Influences ER4943 euismo...

Dec 29, 2025

Cum aluminium structuris colligendis, welders diligenter eligere debent metalla filliorum quae specificam configurationem iuncturam co...

-

Quod Aluminium Alloys bene operantur cum ER4943...

Dec 26, 2025

In modernis aluminii fabricandis, materiam filli rectam eligens saepe determinat num compages iuncta per tempus intentum exerceat. Alu...

Industria Information Extensio

More Information About Special Al Alloy Welding Welding

Breakthrough in Porosity libero Welding Technology: Anti-oxidatio curatio et procession Optimization pro Special Al Alloy Welding Welding

Provectus vestibulum, specialis Alloy Welding filum est magis usus est in industrias ut aerospace, novum industria vehicles et shipbuilding. Sed aluminium Alloy Welding est pronus ad quaestiones ut porosity, rimas et oxidatio, significantly afficiens plenas vires et airtightness. Recens breakthroughs in Porosity libero Welding technology, praecipue per anti-oxidatio curatio et welding procession optimization, habere dramatically melior weld qualitas.

I. Core challenges Special Al Alloy Welding Welding : Porosity et oxidatio

Per Aluminium Alloy Welding, in lacus facile reagit cum hydrogenii (H₂) et oxygeni (o₂) in aere, ducens ad poros. For example, (IV) XLIII Al-Si Welding Wire and (V) CCCLVI al-mg Welding Wire can exhibit porosity rates as high as V% -10% if shielding gas (e.g., Ar or He) purity is insufficient, far exceeding the industry standard of ≤1%.

Key Parametrum collatio:

| Filum type | Typical Porosity rate (Placitum processus) | Optimized Porosity Rate (Anti-oxidatio curatio) |

|---|---|---|

| 4043 Al-Si | IV% -8% | ≤1% |

| 5356 Al-Mg | III% -7% | ≤0.5% |

| MMCCCXIX al-cu (Aerospace gradu) | 5%-10% | ≤0.3% |

II. Breakthroughs in anti-oxidatio curatio

In tardus anti-oxidatio coating pro Al allyy filum utilitas Nano-Alico₃ passivation, efficaciter reducendo hydrogenii effusio per welding. Praeterea, humilis ros punctum protegens Gas (Ros Punctus ≤ -50 ° C) Praeterea minimizes porosity metus.

Optimization Examples:

Filum pre-Purgato: utitur acetone Ultrasonic Purgato ut removendum superficiem olea.

Inert Gas Optimization: Employs ar se mixtum Gas (LXXV% ar XXV%) ad augendae lacus stabilitatem.

III. Welding Processus Optimization: Pulsed Mig et Frigus Metal Transfer (CMT)

Traditional MIG Welding saepe ducit ad nimium calor input, cum pulsed MIG welding et frigus metallum translationis (CMT) welding pressius imperium ad calorem, affectus zonam (haz), reducing poros. Nam exemplum:

CMT Welding potest reducere Porosity in 5xxx al-mg filum per LXX%.

Alterning Current TIG (AC-TIG) est specimen pro 2xxx summus vires Alloy, Minimizing Oxide Slag.

IV. Industry application casibus

Novum Energy vehiculum altilium Tray Welding: utitur er4043 al-si filum CMT processus, achieving porosity <0.5% et testimonii ip67 signa signa.

Aerospace Structural Welding: MMCCCXIX Al-Cu filum combined cum variabilis polarity Plasma Arc (VPPA) Welding delivers Ultra-High-Fortitudo Welds.